With dolly varden siding you get the appearance of bevel and clapboard siding but the convenience of self spacing thanks to the rabbet at the bottom to accept the top of the preceding course.

First course of bevel siding.

Click here to read a short course on cladding part 2.

It is normally blocked out with a starting strip the same thickness as the top of the siding board see figure a.

Installing bevel siding clapboards spacing for the siding should be laid out beforehand.

The manufacturing process results in pieces with one face saw textured.

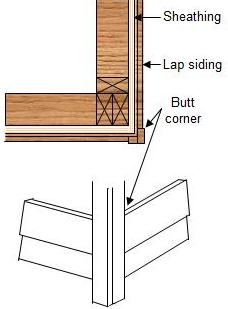

Set the first bevel board in place against the trim at a corner of the house.

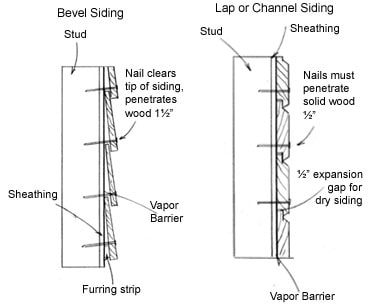

Fasten bevel siding in place using one nail per bearing or stud spaced a maximum of 24 inches on center.

The rabetted bevel dolly varden pattern features a 1 2 3 4 notch in the thicker butt end of the board this rabbeted edge cut allows the bevel siding panels to fit together in such a way as to protect joints from water infiltration.

The dolly varden rabbeted bevel profile is an easier install while providing the same traditional bevel style and appearance.

Start with the bottom course using a furring strip to support the lower edge.

Align the bottom of the bevel plank with the bottom of the starter strip with the end flush against the trim and.

Western red cedar bevel siding is the most widely used siding type.

Each succeeding course overlaps the upper edge of the lower course.

Join the clapboards with scarf joints as in step 3.

Thinner at the top and wider near the lower more exposed part of the board.

Siding may be installed starting with the bottom course.

The most familiar type of wood siding is the clapboard a form of lap siding that s also called bevel siding.

If more than one clapboard is needed to span a wall snap a chalk line between the marks on the corner boards on top of the course being overlapped.

Make sure the first course is level.

Carefully slide the notched piece of siding into place.

Clapboards have a triangular cut.

Siding should be nailed to each stud or on 16 inch centers.

For bevel siding this is a minimum of 1 inch.

It is lumber that has been resawn at an angle resulting in two pieces.

Nail the clapboard to the studs.

On rabbeted bevel siding leave a 1 8 inch expansion clearance.

Each succeeding course overlaps the one below.

Bevel wood siding provides rustic warmth for homes and log cabins.

This is the first of a 2 part series.

Place the nail just above the overlap.

It is produced by resaying lumber at an angle to produce two pieces thicker on one edge than the other.

One edge has a thick butt while the other edge is thinner.

They are lapped to shed water.

When installed it is nearly impossible to tell the difference between dolly varden and bevel or clapboard siding.